Up until the early 1970s, the automotive industry followed a single path for gas vehicles: more power meant a bigger engine resulting in more weight, more cost and, in most cases, worse fuel efficiency. But then came the fuel crisis in the mid-1970s which resulted in an innovative new device that could deliver both power and the fuel efficiency customers suddenly were demanding — the turbocharger. While the first automotive applications appeared in 1962 for racing, the technology truly began its journey toward the mainstream in 1973 with the debut of the BMW 2002 Turbo, proving that smaller engines could punch well above their weight.

It seemed to defy physics — using a new device that turned wasted energy into power for more compression to make a smaller engine behave like a much larger one. In 2011, Ford introduced its version of the turbo, EcoBoost, on the F-150 pickup truck in the U.S. Ford’s bet was that turbos would redefine the industry, including the F-150, even as others were skeptical of customer adoption. Sales skyrocketed, and the industry followed suit: now nearly 75% of F-150 trucks are sold with turbocharged engines(1), and nearly all our gas-powered vehicles offer it.

Today, the industry faces a similar challenge with electric vehicles where the engineering solution for range anxiety has mostly been to increase the size of the battery in the vehicle. But the battery is the most crucial component to tackle affordability because it accounts for somewhere around 40% of the vehicle’s total cost and upwards of 25% of its total weight. Just like when automakers simply made bigger engines, adding more battery makes the vehicle heavier, more expensive and creates a massive physics challenge.

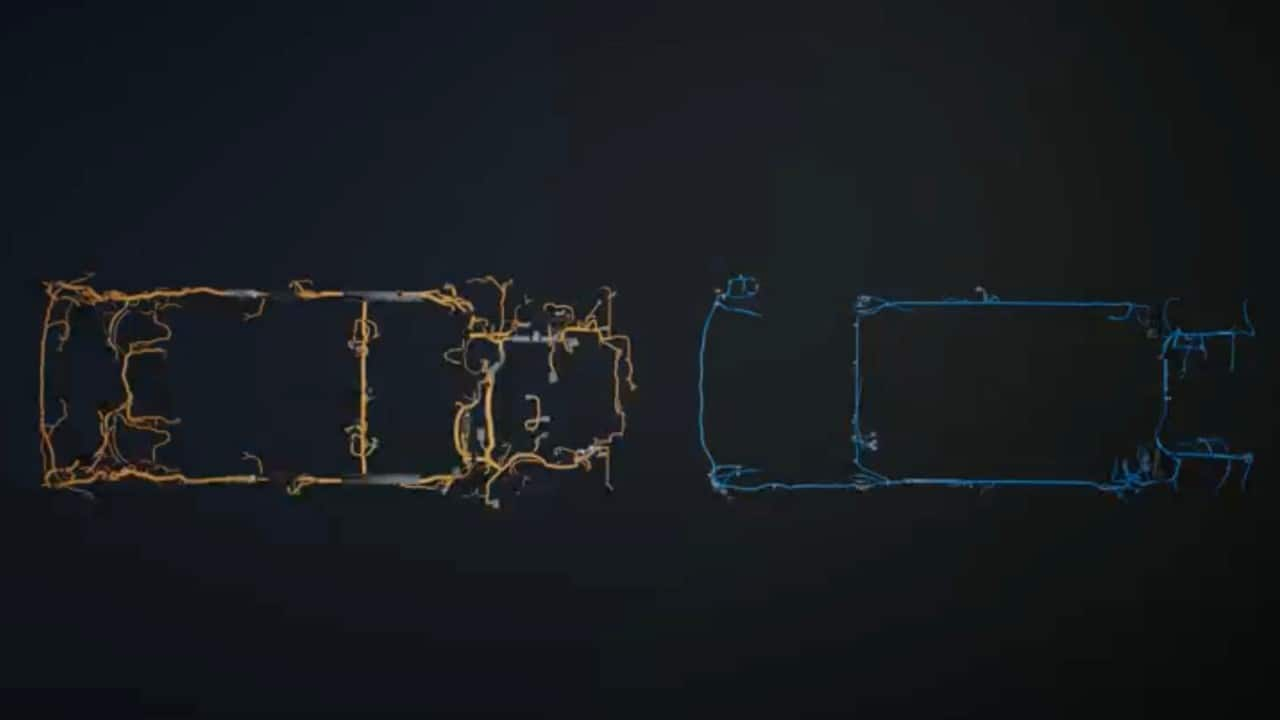

Our big bet for electric vehicles? Obsessing over the vehicle as a system to get more miles out of a smaller battery and radically simplifying the system to reduce the number of parts so we can deliver a new family of affordable electric vehicles to driveways around the world.

Hunting Trade-Offs with Bounties

Affordability is not a marketing tagline for us. To truly make vehicles built on this platform affordable, starting with a mid-size electric truck, we needed to hunt down the cost opportunities. We started by creating a team within the skunkworks operation, tasked with developing range, efficiency and performance metrics for priorities such as weight, drag and rolling resistance and ultimately battery size. They armed every engineer with a new way of evaluating tradeoffs - we call them bounties.