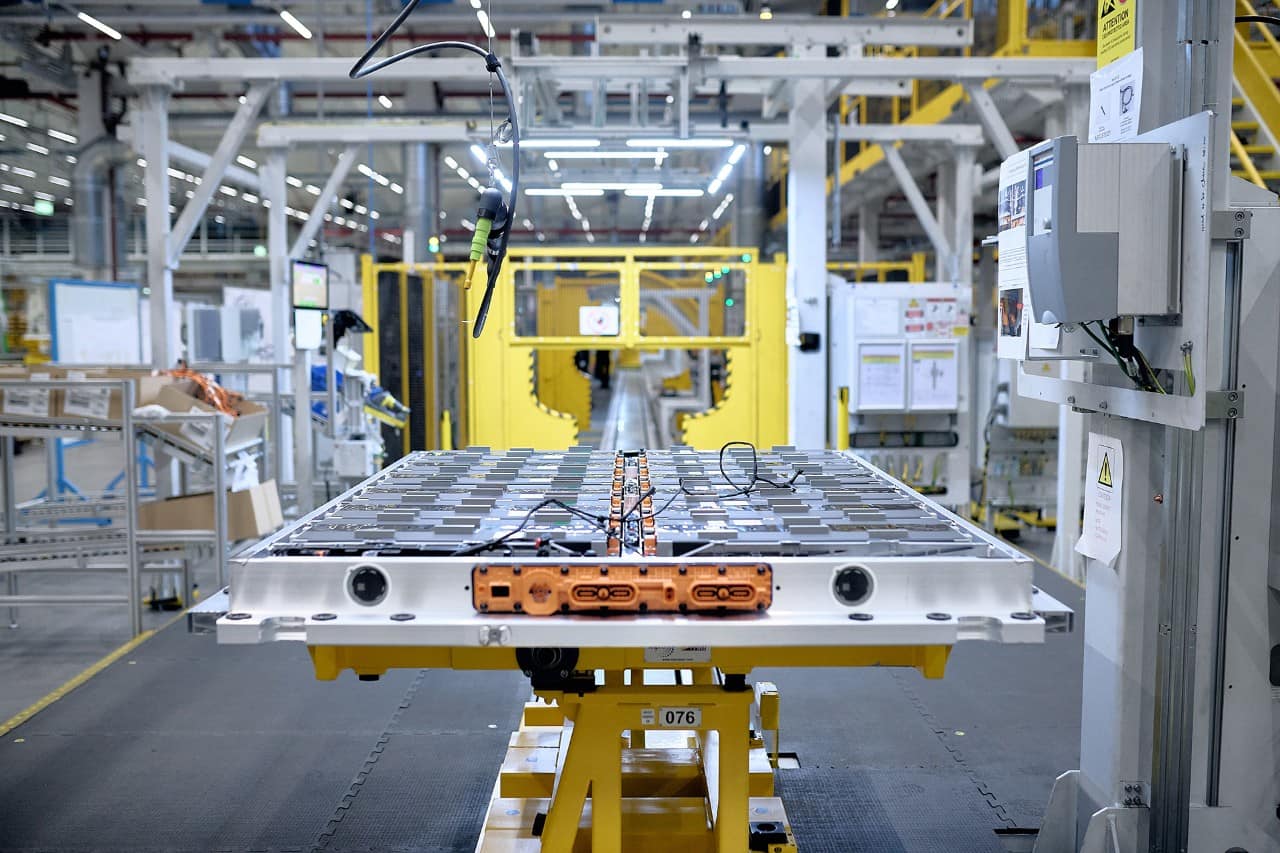

COLOGNE, Germany – Ford has started the mass assembly of vehicle drive battery packs in three different sizes for exclusive use in Explorer and Capri at the Cologne Electric Vehicle Center.

History Made as Ford Begins Capri and Explorer Battery Pack Assembly in Cologne

As part of a transformative $2 billion investment in the historic Cologne plant, the fully digitalised new facility ensures high quality standards, efficiency and a significant reduction in transportation, as well as full alignment with vehicle assembly at the same location.

The Cologne plant has been a cornerstone of Ford production in Europe for almost 100 years. This new plant is another step on the road to electromobility, expanding Ford’s expertise, strengthening value chains and delivering high-quality components and vehicles for customers.

The new Cologne battery assembly plant not only ensures high quality and efficiency, but also includes the continuous development of the skills and expertise of the Ford workforce as part of the transformation of the plant into a digitised Factory of the Future.

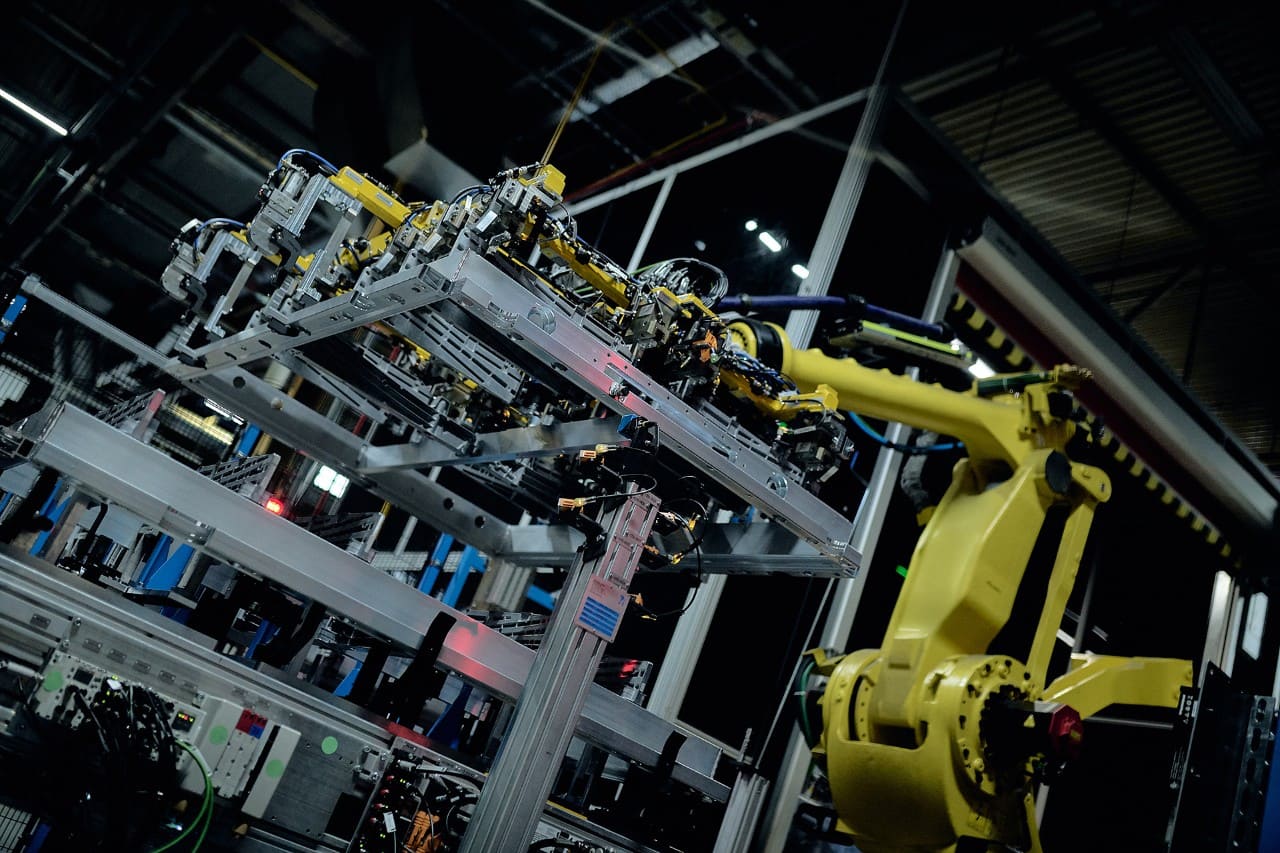

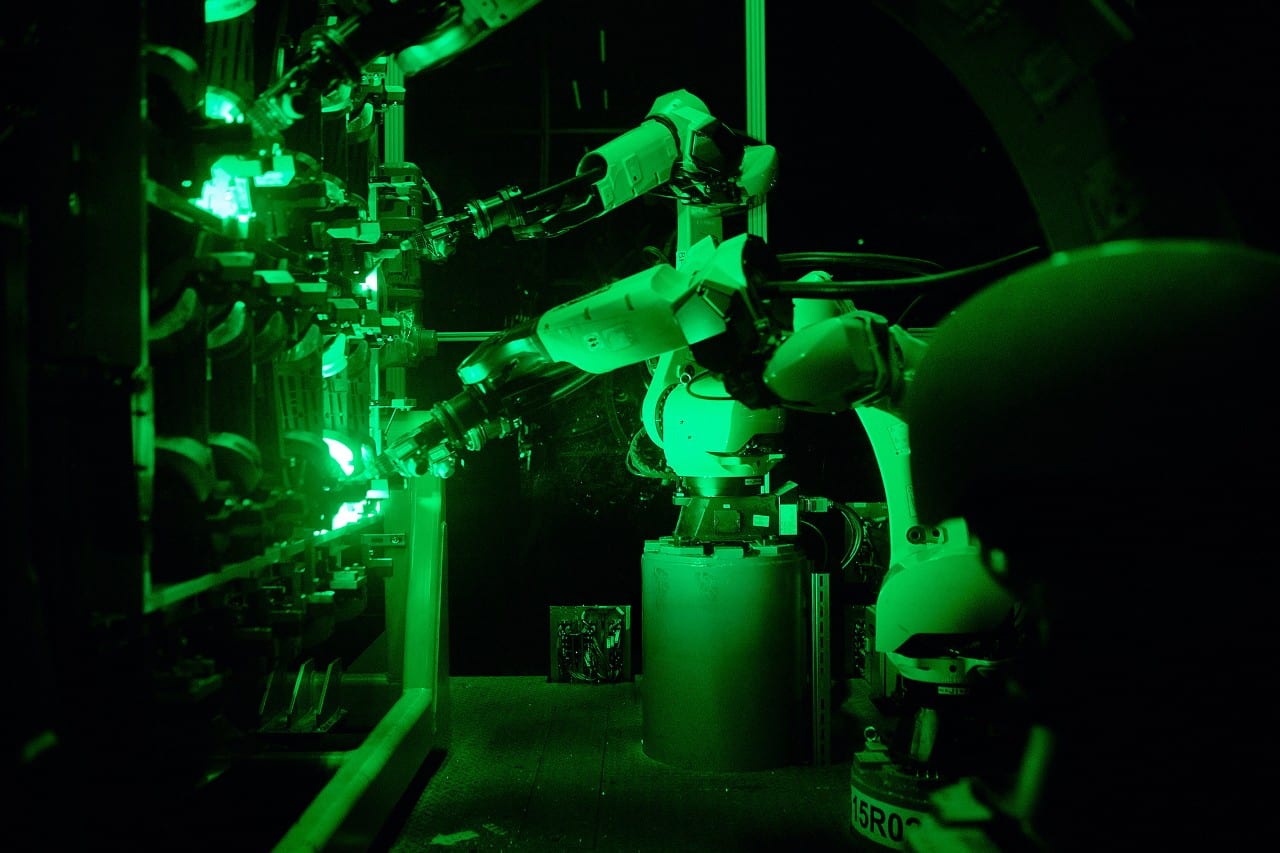

The 180 newly installed robots weld, glue and screw the battery housing together and equip it with up to 12 battery modules. A total of around 2,775 individual parts are assembled into a battery pack on the 2 km-long highly automated production line.

-

Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

-

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries -

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries -

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries -

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries -

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries -

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries -

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries -

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

|Ford’s new electric vehicle battery pack assembly facility in Cologne begins mass production for Explorer and Capri drive batteries

The new battery plant also represents another step in Ford’s journey towards an electric future, updating manufacturing processes and facilities and further expanding its capability in Europe. With electric vehicles also being produced at Ford Otosan’s assembly plant in Craiova, Romania, and Kocaeli, Turkey and electric drive units produced at Ford’s facility at Halewood, UK, Ford is continuing its mission to create a new generation of high-quality electric vehicles in Europe for European customers.